Elements

Our building blocks for a kit

8 insulated wooden elements and blocks for a prefabricated house

Self-building a timber frame house using Gablok blocks

For the construction of a Gablok timber frame extension or house, you will need the 8 formwork blocks made of wood and expanded polystyrene (EPS).

These 8 elements – which make up the timber frame construction kit – are provided for you according to your project requirements.

The goal is for you to receive the exact number of insulated timber blocks you need. This way, your timber frame construction isn’t cluttered with waste and excess materials.

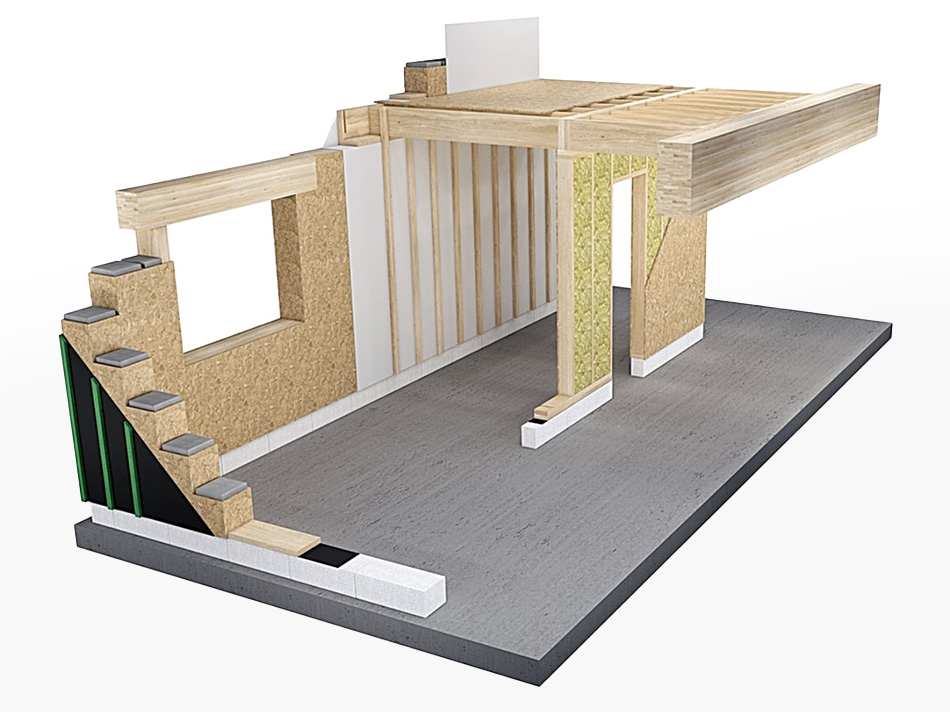

In the diagram you can see in detail how a self-built timber frame house using Gablok insulated wood blocks is organized.

Why UK Builders Choose Gablok

⚡ 5x Faster Construction

Build walls in record time with our precision-engineered blocks

🌱 Exceptional Insulation

Superior thermal performance meets UK building regulations

🔧 No Special Skills Required

Revolutionary interlocking system anyone can master

1

Connecting element: Chevron

to link the kit house

- The (pre-drilled) interior rafters connect the entire wall and create space for the passage of special techniques.

- They are supplied in length and must be placed vertically every 40 cm.

- They will also be used to create the space necessary for the passage of different technical services (electricity, plumbing, etc ).

2

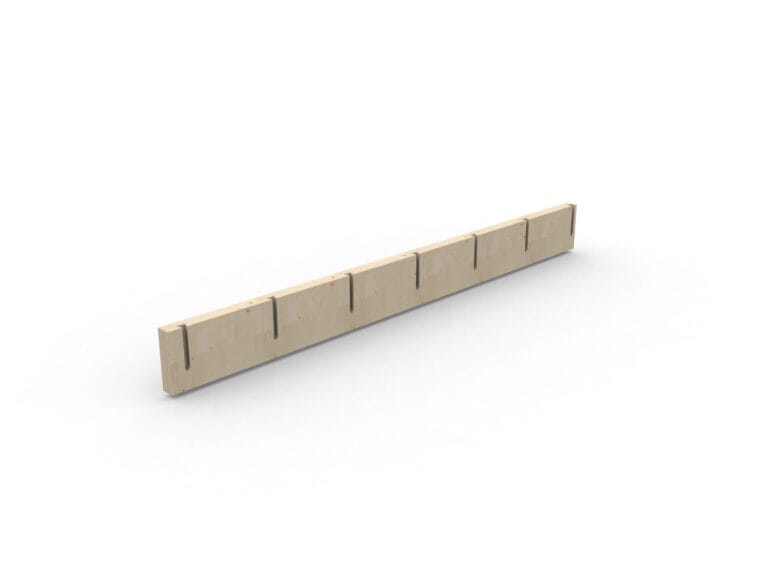

Flooring element

The floor components fit onto the top plate and form the floor of the building.

- The floor system consists of wall plates and joists that fit together in a dovetail joint to form a joist system.

- Our flooring system is sized according to resistance class C24.

3

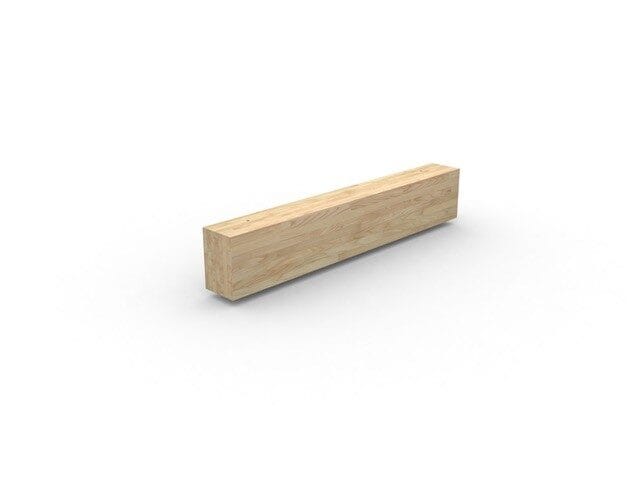

Beam

The beam is used to hold the storeys together, as in a traditional building. It can accommodate heavy spans.

- Made from glued laminated timber, the beam will be used for long spans (window openings > 1.5m, open-plan spaces, etc.). It allows for sufficient spans for most loads.

- The beam supports the weight of the floor.

5

General insulated block

The "classic" insulated wooden block is the one most commonly used in self-build projects. It comes in 3 sizes.

- Available in 3 formats: 300x300x300 600x300x300 900x300x300

- The general insulated wood block is made of OSB 3 and includes 264 mm thick graphite EPS insulation. The resulting U-value (insulation value) is 0.15 W/m²/K.

- The insulation is free to slide in order to form the tenon necessary for the interlocking.

- The "classic" insulated wooden block is the one that will be most used during self-construction.

6

Insulated bottom rail block

The insulated bottom block will be the first one placed on the wooden starting plate.

- This block is designed to fit and cover the starting rail.

- The initial isolated block is the one that will be placed first on the wooden starting rail.

7

Base and top runner

The wooden plates serve as a base for the self-build and connect the belts of blocks.

- Made of 260/45 LVLQ timber, the starting plate will support the first layer of insulated blocks. This starting plate is the wooden element that will serve as the foundation for the self-build. With the same cross-section as the starting plate, the top plate simultaneously connects the entire perimeter beam and supports the floor joists. The bottom and top plates will be joined together by vertically fixed rafters. The top plate, made of glulam, is the wooden element that will serve as the top perimeter beam for the self-build.